The steel industry in Qatar is developing rapidly, and the handling efficiency of steel beams, a core building material in the construction and industrial sectors, has a direct impact on the pace of production. However, steel beams weighing up to 10 tonnes per unit face a number of challenges in the handling process.

Although traditional cranes are capable of carrying heavy loads, they are limited by fixed rails and operating radius, making it difficult for them to penetrate into narrow corners of the workshop to complete accurate handling. Forklift trucks have a slight advantage in flexibility, but due to the limited load-bearing capacity, they are often ‘out of their depth’ when faced with 10-tonne steel beams.

Rail handling equipment is completely path-bound and cannot accommodate the dynamic movement of steel beams between production, storage, and loading/unloading areas. These are the pain points for which the Qatar Steel Company urgently needs a specific transfer cart.

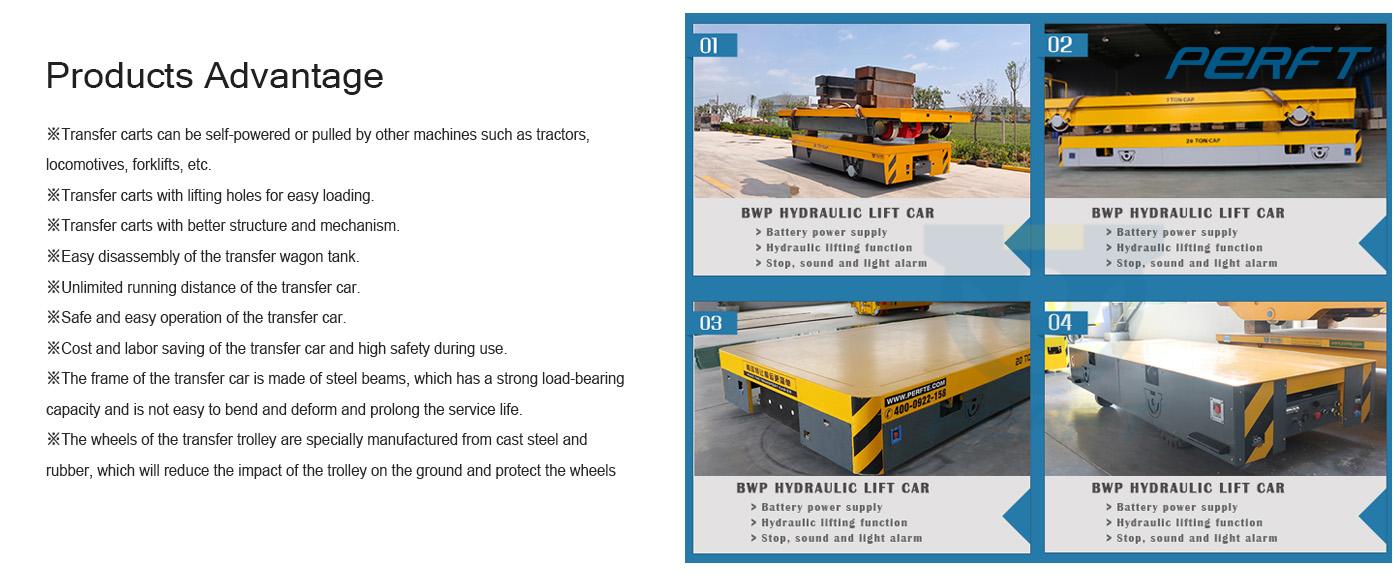

Trackless transfer cart is based on the industrial transfer cart. It inherits the core features of transfer cart, such as economy, safety, and flexibility, and can work directly on the shop floor without complex installation, as well as with cranes and gantry cranes.

As a battery-powered, self-propelled machine, it is manually guided and has a 10-tonne rated load to match the weight of the steel beam precisely. At the same time, it is capable of 360° steering and in-situ rotation, making it easy to cope with the complex layout of Qatar’s customers’ steelworks.

Unlike cranes, which rely on working at height, or forklifts, which are limited by counterweight balancing, trackless transfer cart always operates at ground level, just inches above the ground. The design breaks the ‘first in, first out’ fixed path limitation and allows free route planning according to the steel beam’s transfer needs, filling the gap between traditional equipment in confined spaces and flexible scheduling.

Accurately Matching the Handling Demand

All wheel steering transfer trolley 10 tonne rated load is specially designed for standard steel beams, which not only avoids the safety hazard of ‘overloading operation’ of small tonnage equipment, but also eliminates the resource loss of ‘wasting empty loads’ of large tonnage equipment, and realizes perfect matching of load and demand. The perfect match between load-bearing and demand is achieved.

Maximise the Use of Workshop Space

The in-situ rotation function allows the machine to be turned within its own footprint, without the need to reserve additional operating space. This feature enables steering transfer trolley to travel efficiently through the narrow aisles and equipment gaps in the steel workshop, increasing the utilisation rate of the workshop’s usable area by more than 30%.

Freedom from Path Constraints, Flexible Scheduling

The battery-powered design completely eliminates the constraints of fixed rails, allowing the steel beams to be transported from the production line to warehousing and storage, and then to the trucks for shipment, all from the same trackless transporter. Whether it is a short-distance transfer from the production area to the storage area or a long-distance transport across workshops, it can be seamlessly connected.

Synergise with Existing Equipment

Trackless transfer cart for steel beam can form an ‘air + ground’ three-dimensional handling network with workshop cranes and gantry cranes. When the crane lifts the steel beams from the production line to the ground, 10 ton transfer cart can immediately take over and transfer them to the corners that are difficult to cover by the crane, thus solving the ‘last kilometre’ handling problem.

While traditional steel beam handling requires the cooperation of 3 persons: crane operator, hookman, and safety officer, trackless transfer cart requires only 1 operator to complete all operations by remote control. Based on the local labour cost in Qatar, a single unit can save more than 100,000 Qatari Riyals in labour cost per year.

Trackless transfer cart for steel beam is simple to operate, and new employees can be on duty after 1-2 days of training, much lower than the training cycle of cranes (1-2 months) and forklifts (2-3 weeks). At the same time, the single-operator mode simplifies the personnel management process and reduces the communication costs arising from multi-person collaboration.

The low-centre-of-gravity design and the ground operation mode reduce safety hazards such as falling from height and overturning of heavy objects from the root. The operator can be guided on foot alongside steering transfer cart, with a 360° view of the surrounding environment, eliminating blind spots. This feature makes industry transfer cart fully compliant with Qatar’s stringent industrial safety standards and reduces downtime, maintenance costs, and fines due to safety incidents.

The table surface of trackless handling equipment is made of non-slip and wear-resistant material, and is equipped with adjustable stops to ensure that the steel beam is stable and free from shaking during the handling process. The length of the table can be customised according to the length of the steel beam, which avoids deformation during handling.

The battery life of trackless transfer trolley for steel meets 8 hours of continuous operation, completely covering the needs of a production shift. At the same time, transfer trolley can be equipped with a high-temperature protection layer, so that it can still operate stably in the high-temperature environment of Qatar’s steel workshops. For dusty and flammable environments.

Depending on the layout of the workshop, transfer cart 10 ton is available in a railed or trackless design, with an optional four-wheel drive system to ensure smooth handling of steel beams on uneven floors, from the table size to the drive mode.

Transfer cart 10 ton is the ideal solution for steelmakers in Qatar, with its precise load-bearing design, flexible handling, and significant cost advantages.

Whether you’re a large steel mill or a small to medium-sized processor, trackless transfer cart is the ideal solution to your steel beam handling challenges – improving efficiency, reducing operating costs, and ensuring safety. For customised solutions, contact us today, and we will provide free site surveys and design services to make your steel beam handling more efficient, safer, and more economical.